The airline industry has been hit hard by the ongoing pandemic. Dropping travel demand, travel restrictions at the borders and travellers lack of confidence in airplane travel has put the global aviation industry into the biggest financial crisis since 9/11. Airlines are struggling, with many in danger of immediate collapse, and experts predict that it will take years for the industry to fully recover from the impacts of the pandemic. It’s not just airlines that are suffering from low travel demand and astronomical revenue loss; many support sectors in the air transportation field, such as the airport ground handling service, airline catering service, airport retails and commercials, are all experiencing the turbulence of pandemic. Job cuts and salary adjustments have already become way too familiar in these sectors in the past few months as the coronavirus pandemic has wiped out tens of thousands of jobs in the aviation field and grounded most of the airline fleets.

Unprecedented Challenges And New Opportunities For Airport Ground Operations

With the positive incoming news regarding the development of vaccines and planned mass vaccination happening soon, hope is on the horizon. In fact, even though during the pandemic period we saw a sharp decline in passenger volumes across the board, cargo flights were booming in business as they formulate vital links and connections between countries. They are the critical workforce in the global logistics network, transporting and distributing time-sensitive and temperature-sensitive pharmaceuticals, personal protective equipment and vaccines between countries. Additionally, as the coronavirus testing technology continues to evolve, rapid testing has been widely applauded by the airlines as a scientific and effective method to restore traveller’s confidence in airplane travel along with the ease in border restrictions and quarantine rules. In the foreseeable future, with vast immunization across the world, the establishment of travel bubbles between countries, and the introduction of immunity passports, we are expecting travel demand to quickly pick up soon.

Extraordinary times call for extraordinary actions and responses. Airport ground handling crews are the most pivotal group of employees working the frontlines by supporting the airport operations and aircraft movement 24/7. Most work directly for airlines or contracted ground handling companies, and their positions and tasks can range from providing customer service, ramp services and conducting aircraft maintenance. We will primarily focus on the ramp service crew and see how their work enables the airport to function smoothly throughout the pandemic. We are also going to explore how technology tools power them through the everyday workflow.

Ramp agents are responsible for a variety of tasks, including loading and off-loading baggage and cargo, directing planes to and from their gates, de-icing airplanes, operating baggage carts and pushback tractors and many more activities. It requires a collaborative effort between multiple departments to service each aircraft. In busier airports, ramp service agents may need to service multiple aircrafts at the same time, which demands a high level of precision, accuracy and efficiency.

Airport operations and air traffic movements follow a strict set of schedules and plans where each flight is assigned with a dedicated take-off and landing slot. Any ground operation delays for a flight could have a domino effect on other flights, resulting in a more wide-spread delay across the airport and disrupting regular traffic flow. Air traffic controllers have to reassign new departure windows to each following aircraft and adjust airport departure rates and arrival rates to bring the airport operations back to normal. The longer the airplanes are sitting at the gates, the more money airlines are losing. Airlines need airplanes to stay in the air as much as possible to turn profits. Airplanes sitting on the ground will keep burning cash as airlines need to pay crew members as well as aircraft and ownership costs. Lengthy delays could also negatively affect passenger satisfaction. During the pandemic, airlines were focusing on preserving cash flow and revamping their operations and business models to survive this challenging period. Any ground delays can further impact a business’s long-term financial status, which threatens the airlines future. Poor on-time performance can also drive away loyal customers, which is a huge loss for any airline during the pandemic and may slow down the economic recovery of the business after travel demand picks up again.

All of this demonstrates that airport ground handling service must be done in an efficient and cost-saving manner in the post-pandemic world to support the recovery of the aviation industry. The new standards pressure the ground service contractors to use the least possible labour and adopt all cost-cutting measures but maintain the same level of service and quality. It may seem impossible to balance these conflicting factors, but modern technology has showcased proven solutions that help ground service contractors and agents to fly through operational tasks with mobile computer vision.

Introducing telematics — one of the most reliable and widely adopted assets and human resource management systems that completely transforms how ground operation managers and equipment operators navigate their day. We will go through 8 different ways of how telematics can simplify workflow, maximize productivity, drive down costs and secure operations.

Stay On Top Of The Operations

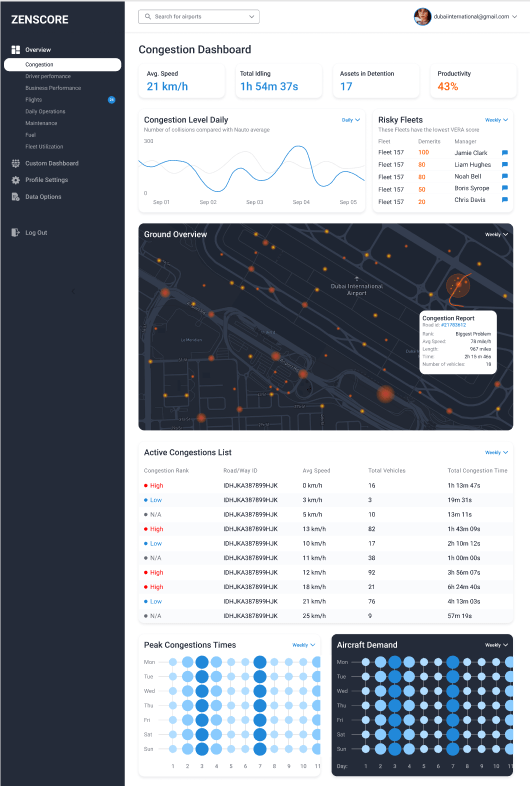

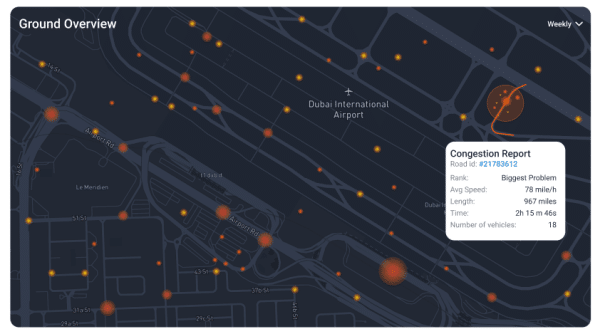

When you have so many airport assets and vehicles to manage, you need to stay on top of the entire operation. With telematics, getting a full picture of the fleet and operations on any device could not be easier. Our scalable system automatically compiles all the critical information and displays it on one simple intuitive map which gives you full visibility and control of the operations.

Streamline Work Process From Start To Finish

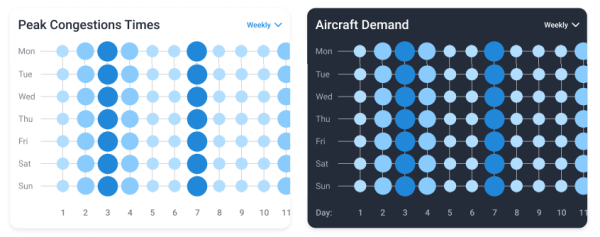

Our system can be easily integrated with airport systems and IT infrastructures, where the system automatically establishes work orders, determines priorities and assigns work to equipment operators. The whole process takes into consideration multiple factors, including aircraft pushback time, arrival time, the amount of workload for ground handling agents and an estimation of how long it will take to complete the work. The system algorithms are designed to optimize and best utilize the available resources to ensure timely pushback of every flight. By giving equipment operators a clearer view of their upcoming tasks and the information of the aircraft they need to service next, they can more efficiently plan out their day and improve their productivity.

We also focused on providing a simplified workflow for fleet managers. Our innovative dashboard is the ideal place where fleet managers can find a summary of all the real-time fleet critical metrics and data. Our system can automatically notify fleet managers if a disruption happens during the ground handling operations that may result in a pushback delay for the aircraft, so that fleet managers can be alerted and take appropriate responses such as dispatching extra resources to mitigate the impacts.

The Most Expansive Customization, Right In Your Hands

The airport is a very unique and special setting where rules need to be strictly enforced. We provide the most expansive list of software and hardware customization options, so you can have complete freedom to create systems, dashboards, maps or hardware packages that best serve your interests and key focuses. Geofencing is a powerful tool in our system where fleet managers can set up predefined boundaries, establish special rules and restrictions to control asset movements and provide clear instructions to asset operators. It allows fleet managers to draw zones around places of work to create a highly organized workflow that drastically improves airport operation efficiency.

Safety Is A Top Priority

Safety is a top priority in any workplace. This is especially true for airport operations, where any collision and accident can be costly and catastrophic. This is a place where safety rules have to be strictly enforced, and no mistake is allowed. In responding to the stringent safety measures and standards, telematics solution providers offer a comprehensive 360-degree protection solution that could have a meaningful impact on the operations. The collision avoidance technology, driver distraction camera and all-angle vehicle camera system, form a multi-layered safety protection net that effectively reduces the possibility of collision and accidents. The driver scoring dashboard is the first-of-its-kind in the industry that adopted advanced sensing technology to assign a safety score for each equipment operator, helping to promote good driving behaviours among the fleet.

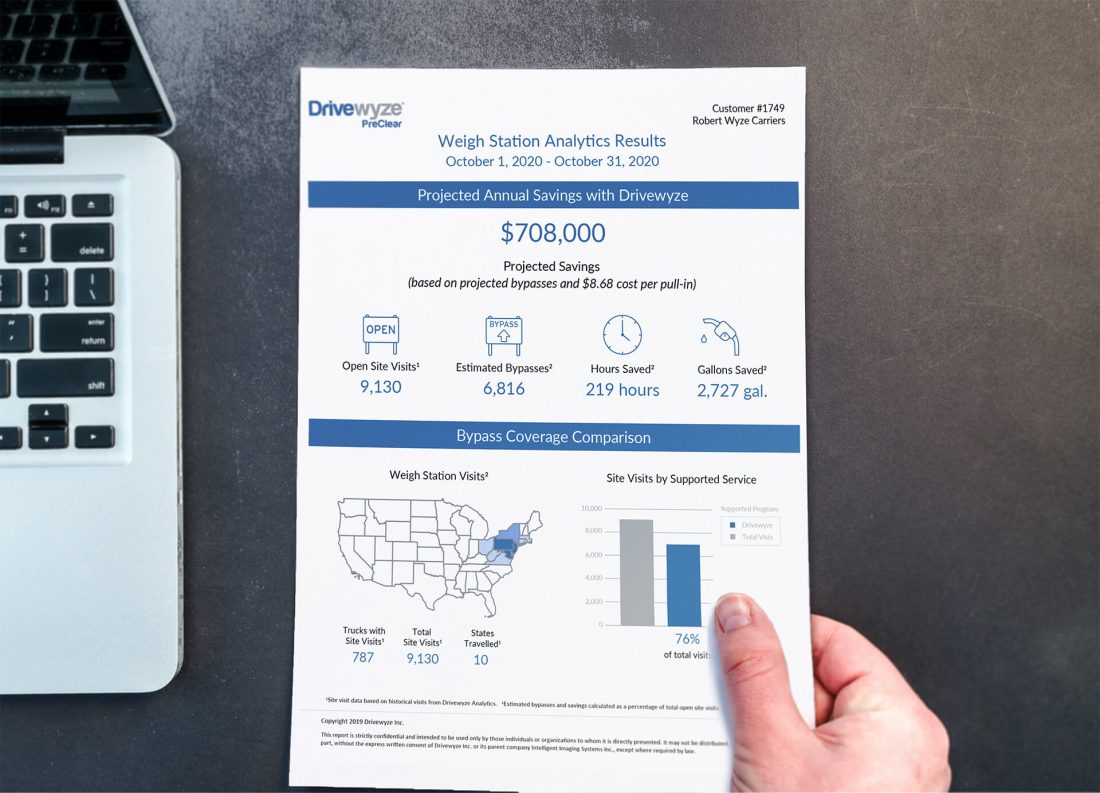

Real Saving That You Can See

Throughout the pandemic, we learned that businesses are putting an increased focus on cost management. For heavily impacted sectors, such as the aviation industry, companies and airlines are searching for every opportunity to cut down on unnecessary costs and preserve important cash flow. For ground operations, fuel is one of the top expenditures and managing fuel consumption has been the number one priority for ground service contractors and airlines. However, you cannot effectively cut down on fuel consumption without first knowing all the fleet’s critical energy consumption data and metrics. Telematics is the central platform enabling fleet managers to monitor fuel consumption, set up targets for minimizing the costs and to keep an eye on the overall fleet costs. Our package includes leading sensor solutions, helping fleet managers extract vital information from vehicle parts and components. Our software utilizes advanced algorithms and machine learning models to analyze data and create tailored step-by-step solutions to assist fleet managers in driving down costs.

Small Steps, Big Difference

We deeply care about the environment, and that’s why we integrate features allowing fleet managers to measure the fleet’s environmental and carbon footprint. Our vehicle’s onboard sensors can help fleet managers track drivers’ behaviours such as harsh braking, engine idling that directly affect fuel consumption and carbon footprints. The road navigation system integrated with our telematics platform always assigns equipment operators with the most efficient route to their destinations in the airport, slashing both carbon footprints and fuel spending.

Your Asset, Now Secured

Fleet managers never want any unauthorized individual to operate airport equipment. Our telematics solution packs in an encrypted onboard driver authentication feature where only operators and personnel that hold the authorized ID card can access and operate the vehicles. This type of controlled access can clearly reduce unauthorized equipment usage and eliminate injuries to untrained, non-qualified crew members.

Protect Your Fleet – With Proof

Accidents that happened at the airport can be devastating and extremely expensive. Think about what if one of the ground handling equipment collides and damages the airplane; who should be responsible for the damage? When it comes to determining liability and responsibility, fleet managers need to equip the vehicle with the right tool, such as dash cameras, to help them document the event and analyze who was at fault. It’s a handy add-on that can protect your business and prove your operators are not at fault during an accident, which can save your business from paying hefty compensation that you actually should not be responsible for.

The aviation sector will prevail and bounce back eventually. Though nobody can be certain about when people will be confident to fly again, airlines and ground handling companies are devoting all efforts to ensure they can navigate through the turbulent time and come back in a stronger position. The effects of the pandemic will be felt in aviation for several years to come, but we are ready to give a helping hand.

Our industry-leading telematics solutions provide the necessary support to help your business deliver high-quality service during the pandemic and build resilience to endure hardship. Speak with our industry-specific specialists to discuss how we can help your businesses to fly high during this unprecedented time.