Construction sites don’t fall apart because of one big mistake. It’s the little things—the missed check-ins, the missing equipment, the “we’ll fix it later” moments—that pile up fast. Before you know it, you’re looking at project delays, budget overruns, and a team that’s doing its best to stay afloat.

And it adds up fast:

- Tool theft alone costs the construction industry over $1 billion annually

- Labor accounts for up to 50% of total project costs, and inaccurate time tracking makes that number balloon

- The average construction project faces cost overruns of 16% and delays of nearly 20 months

Most of these issues? Completely avoidable.

Manual processes, scattered oversight, and guesswork leave room for errors that shouldn’t happen in the first place. Especially when timelines are tight, crews are rotating, and the cost of downtime hits hard.

This isn’t about working harder. It’s about having the right tools in place so your team can actually work smarter—without constant fire drills.

In this article, we’re breaking down the common issues that keep popping up on job sites—and showing how modern construction fleet tech can help you put a stop to them once and for all.

When Time Tracking Turns Into a Guessing Game

Let’s be honest—manual timecards weren’t cutting it even when job sites were simpler. Now, with rotating crews, multiple subcontractors, and pressure to hit deadlines, relying on scribbled names and punch-in times just doesn’t hold up.

The result? Hours that don’t add up, inflated payroll, and delayed starts because check-ins take too long—or get skipped altogether.

And if “buddy punching” is happening behind the scenes? That’s money walking off the site every week.

Here’s how leading construction crews are closing those gaps:

- Mobile and Bluetooth-based workforce tracking ensures every check-in is real, accurate, and location-verified—no more guesswork or ghost hours

- Digital logs with automatic time and location stamps keep your records tight and your payroll process clean

- Real-time visibility helps reduce unauthorized site access, which means a safer, more controlled job site

Construction leaders using this setup are seeing results like:

- Up to 30% more accurate payroll

- Up to 60% fewer unauthorized visits

No spreadsheets, no chasing signatures. Just a smooth, reliable system that keeps your workforce where they need to be—and your budget where it should be.

Lost Equipment Shouldn’t Be a Line Item

One missing power drill is annoying. A stolen skid steer? That’s a serious hit. And it happens more than anyone wants to admit.

Construction sites are busy, high-traffic zones—perfect for tools to get “borrowed,” misplaced, or taken altogether. When equipment vanishes, so does time, productivity, and budget. Crews are left waiting. Timelines slip. And you’re stuck sourcing a last-minute replacement or eating the cost.

Here’s how smart tracking puts a stop to all that:

- GPS and Bluetooth asset tracking helps you keep tabs on everything from hand tools to heavy machinery, in real time

- Geofence alerts let you know immediately when an item leaves a designated area, so you can respond fast

- Motion-triggered security cameras add an extra layer of protection after hours—deterring theft and flagging suspicious activity before it becomes a problem

Real example? A skid steer was driven off-site after hours. A geofence alert triggered immediately, and the foreman recovered the machine within minutes—before any paperwork or replacement orders had to happen.

It’s not about tracking every move. It’s about keeping what’s yours where it belongs—and making sure work doesn’t come to a halt over a missing tool.

Breakdowns Don’t Just Kill Equipment—They Kill Momentum

You’ve got crews lined up, materials delivered, and tasks scheduled down to the hour. Then, one critical machine goes down. Suddenly, everything stalls—and so does your timeline.

Unplanned maintenance is more than just an inconvenience. It leads to missed milestones, budget blowouts, and sometimes, strained client relationships. And the worst part? Most breakdowns are preventable with the right heads-up.

Here’s how modern construction teams are staying ahead of the problem:

- Predictive maintenance tools monitor engine hours, fault codes, and wear patterns to flag issues before they escalate

- Automated service reminders are triggered by actual equipment usage—not a calendar—so you’re not relying on guesswork

- Data-backed maintenance logs help extend asset life, lower repair costs, and keep projects running on schedule

Crews using predictive maintenance have seen up to 40% fewer unscheduled breakdowns. That’s more uptime, more productivity, and less scrambling to rent or replace machinery on short notice.

When your equipment shows up ready to work, so does your team.

Safety’s Not Optional—But It’s Still Getting Skipped

No one sets out to cut corners on safety. But when the pressure’s on and checklists live on clipboards, it’s easy for things to get missed.

An inspection gets delayed. A safety form goes half-filled. A machine gets used without a pre-check. And just like that, the site is exposed—to real danger, and real liability.

Here’s how construction teams are making safety a no-skip step:

- Mobile safety forms with required fields ensure inspections and checklists actually get completed before work begins

- Automated reminders prompt operators before using machinery, so nothing slips through the cracks

- Centralized digital records make it easy to pull up past audits, logs, and checklists if a review or incident ever comes up

The result? Crews complete 40% more safety checklists, and site managers get peace of mind knowing compliance isn’t a “nice to have”—it’s already handled.

Because when safety is built into the workflow, it doesn’t get skipped. It just gets done.

You Can’t Be Everywhere—But Your Data Can

Managing one job site is tough. Managing three (or ten) without live visibility? That’s just asking for blind spots.

And blind spots cost money—whether it’s idle equipment, an unsupervised delivery, or unexpected site activity after hours. When site managers are stuck relying on delayed updates or secondhand info, decisions slow down, problems pile up, and oversight gets shaky.

Here’s how the right tools put you back in control:

- Portable, cellular-connected cameras give you live visibility across multiple job sites, no Wi-Fi required

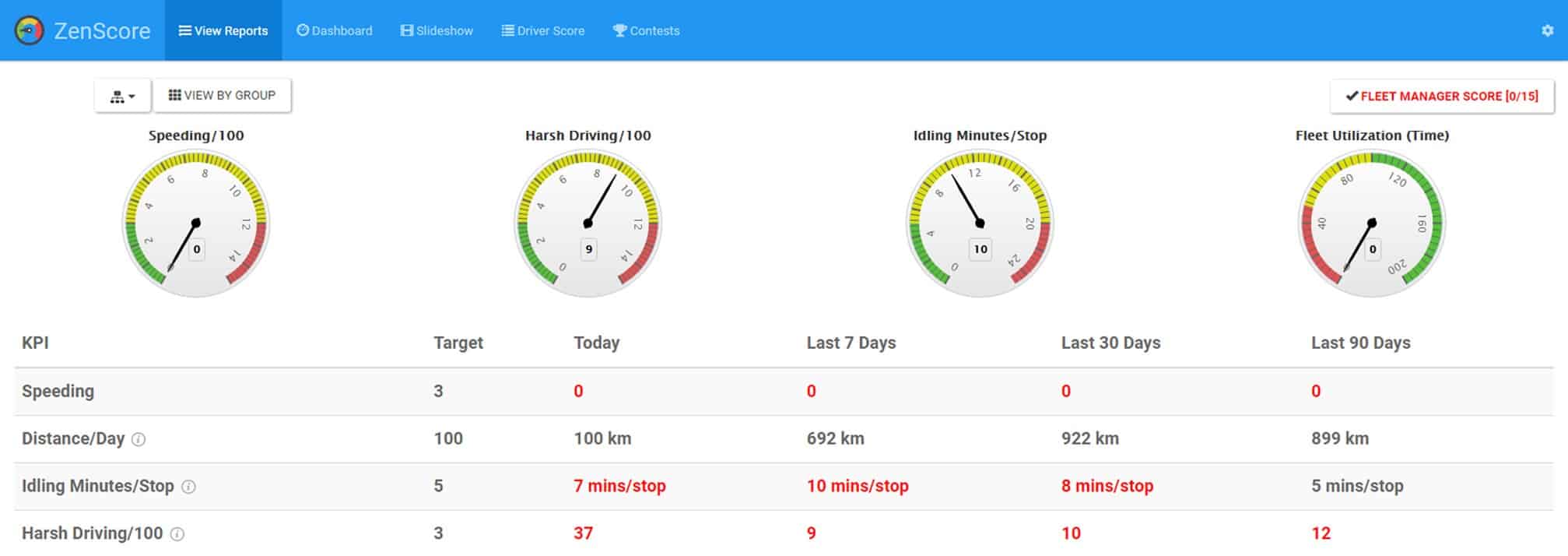

- Real-time dashboards show you workforce activity, equipment movement, and site conditions in one view

- Instant alerts flag motion after hours, prolonged inactivity, or unauthorized equipment use—so you can act fast

Example? A camera picks up unexpected movement at a closed site late at night. An alert goes out instantly, and the ops manager steps in before a $50,000 theft happens. Problem avoided. Budget saved.

When you have visibility, you don’t have to chase updates. You already know what’s happening—and what to do next.

The Tools That Take You From Scrambling to Solid

When you’ve got eyes on every site, every tool, and every team member, things start clicking into place. Equipment stays where it should. Crews stay on track. Safety gets handled without reminders.

And that’s not just good for your day—it’s good for your margins.

Here’s what the most efficient construction teams are using to stay ahead:

- GPS & Bluetooth Asset Trackers

- Workforce Mobile Check-Ins

- Motion-Activated Site Cameras

- Predictive Maintenance Monitoring

- Geofence Alerts for Equipment Movement

- Digital Safety Compliance Forms

- Centralized, Real-Time Dashboards

No more paperwork piles. No more guessing games. Just one system that gives you the control, speed, and clarity your sites have been missing.

You Can’t Afford to Operate Blind Anymore

Construction isn’t getting easier—or cheaper. Every missed check-in, every breakdown, and every tool that disappears without a trace chips away at your timeline and your profits.

But here’s the shift: you don’t have to run job sites in the dark anymore.

With affordable, scalable tools like GPS tracking, automated check-ins, and predictive maintenance, you can stay ahead of the issues that used to slow you down.

Want to see what full-site visibility really looks like?

At GoFleet, we help construction teams take back control—by reducing theft, streamlining safety, and giving managers a real-time view of their operations.

Book a demo today and start building smarter, safer, and more profitable job sites.