In any industry, workplace safety is of critical importance. Industries where contract workers are hired by authoritative management corporations to complete tasks in dangerous sectors, often find themselves looking at how they can improve safety measures.

As many tasks in these fields require the use of heavy machinery or the movement of large and hazardous items – many are looking at how telematics advancements can help.

Hiring In Dangerous Sectors

To fully understand the need to implement safety measures via telematics, the hiring process must be understood in dangerous sectors such as construction, transportation, forestry or logging and even mining and oil. In these industries, businesses often outsource work by hiring contractors rather than hire full or part-time workers. There are number of reasons why:

Productivity and Finances

Often in these dangerous sectors, this type of work is seasonal. This means that workers are only required at certain times of the year. Corporations prefer the flexibility of outsourcing work, so they do not have to deal with the administrative challenges of constantly having to layoff workers at the end of each busy season.

Corporations understand the massive financial benefits of outsourcing to contractors. Operations managers discovered that by hiring seasonally, they can perform cost comparisons in terms of productivity and pay for all workers.

They are able to perform such comparisons during the season to monitor and re-hire the best-performing contractors. As a result, corporations can maximize their productivity and revenues, allowing them to remain competitive in an aggressive marketplace.

Reduced Liability

By outsourcing work and hiring seasonal contractors, many corporations also find that they can improve their liability risk. This enables their business to be more focused on supplying the proper safety requirements, while the actual need to carry out safe work practices are shifted to a constructor or general contractor who undertakes ownership of the project.

It is important to highlight that corporations will be required to ensure safety in the means of: (i) ensuring proper training is available; (ii) all workers and supervisors are properly trained on safety policies or precautions; (iii) have the appropriate safety tools; or (iv) the proper equipment and safety environment to protect the workers.

This means that the constructor is responsible for ensuring that all workers on site are complying with safety policies, procedures and obligations – or inadvertent liability.

Risk Evaluation and Assessment: Onsite and Offsite

In sectors where authoritative management governs worksites, the concern of safety does not end there. There are risks when workers are moving supplies or travelling between sites. When risk is evident in numerous locations at varying times, the need to collect and analyze data to evaluate risk becomes even more critical.

Onsite Risk

Onsite risks are typically limited to the immediate actions of contractors. Often this refers to the knowledge of training and precautionary measures taken by workers while completing tasks. For example, knowing how to safely harvest timber and load lumber into the flatbed of a truck with the use of heavy machinery. When proper training and undamaged tools or equipment is utilized, the onsite risk is significantly lowered.

Offsite Risk

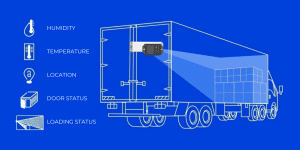

In comparison, offsite risks are factored-in to the immediate actions of contractors – as well as their working environment. As much as offsite risks arise when goods are being transported, contractors must be attentive to their surroundings. A wide range of unpredictable incidents can happen at any job site – including injury, road clean up and even lost resources.

A business can mitigate the risks by having pre-trip checks on the vehicle or implementing tools to ensure that strict safety protocols are being followed.

How Authoritative Management Can Reduce Risks

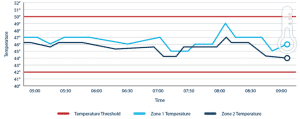

To properly reduce risk and liability concerns, fleets in these dangerous sectors must investigate risks and assess danger in the field. To better understand current initiatives and procedures, companies must evaluate key historical safety indicators – which will shed light on how efforts may need to change.

In order to fully understand your current KPIs and solutions framework, a telematics assessment should be performed. It’s important to note that while solutions may have several advantages, it is critical to understand how the solution will specifically target safety.

There are three options that can be implemented in industries that are dangerous or hazardous for its workers.

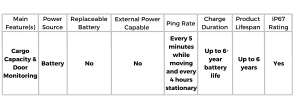

1 Sensorizing Your Fleet

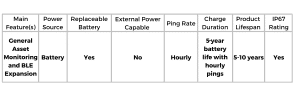

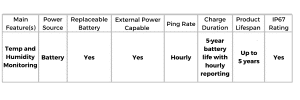

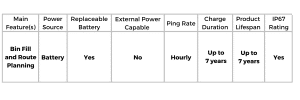

Installing sensors throughout your fleet can minimize risk as the devices can act as a safety precaution. Since the technology transmits various data internally, many corporations have found sensors to be useful for the following: displaying real-time GPS location, displaying alerts or notifications and confirming weight or load requirements.

When sensors are installed onto equipment or vehicles, teams can know the exact movement of the asset it is attached to, in addition to certain compliance requirements that may need to be met – such as weight or load. However, one important use to highlight is the alert system for trip inspections, as the sensor can convey whether certain safety precautions are faulty. This means that unsecure lids or caps, loose straps, completed walk around checks or even whether a contractor has the proper training on file to use certain equipment can be detected.

2 Increased Visibility With Cameras

Cameras can be installed throughout fleets to monitor the use and performance of vehicles and heavy equipment. Not only can this record the events in view of the device, such as general employee safety on site, but it detects whether contractors are using the equipment properly while moving between two points.

The most important feature of using the cameras, however, is to perform incident reviews when there is an accident, reported issue or complaint of delay. By having footage readily available, site managers are able to review what happened rather than rely on worker or civilian recollection. Meaning proper actions like additional training, suspension, or understanding of liability and fault can happen.

3 Safety Scoring And Training Integrations

As previously mentioned, cameras can be used to help shed light on more training opportunities. Specifically, equipment use via engine monitoring and camera surveillance can be used to determine safety scores for each worker. This allows for performance ratings to be completed and even allows for training or site suspension to be assigned based on the person’s skills or knowledge of procedures.

Use Case: Forestry and Logging

To ensure safety in a high-risk sector like forestry, many authoritative corporations are implementing telematics solutions throughout their operations. Such telematics solutions include the three previously discussed tools: sensors, cameras and scoring or training systems.

By sensorizing fleets, corporations in logging are able to ensure that certain actions are always taken and even set up alerts to notify workers when certain actions were not taken. This is specific to the loading process on a logging site when lumber is placed on flatbed trucks to move it to the millsite. Since these vehicles are moving thousands of pounds of lumber, if straps are not secure, cargo can find its way off the vehicle while on route. If this happens, regardless of whether it is on public or private roadways, death and injury of a bystander becomes a real concern.

Fleets that install cameras on vehicles and heavy machinery find that they can better monitor the behaviour of employees – focusing on whether individuals are acting safely by following procedures. This enables companies to flag safety concerns. Such concerns include insecure loads being dispatched or contractors forgoing pre-trip checks.

Cameras are also useful when offsite vehicles can sometimes be involved in accidents involving civilians, such as accidents with other vehicles or dangerous driving. Verifying what really transpired by reviewing the driver footage can shed light as to what truly happened and who was at fault. It can also provide a resolution framework as incidents are documented and structural changes are made to rectify them

Lastly, all of the information collected on employee behaviour can be reviewed and submitted into a scoring system. Meaning managers can see who is following safety protocols and who may need additional training.

To learn more about how telematics is being used right now, check out our recent success story that features Forest Trotter by clicking here.