The COVID-19 pandemic has affected everyone’s day to day life and significantly disrupted businesses’ routines and operations. People are all anxiously hoping for an end to the crisis and a return to normalcy, as soon as possible.

After months of patiently waiting, everyone remains cautiously optimistic that a vaccine is on the horizon – in the near future. The only question is when will it be widely available? By asking the question “when”, we don’t mean when the vaccine will be ready or approved, but rather when will the majority of the population have access to the vaccination.

Distributing and transporting vaccines tends to be an even greater challenge than the development of vaccines. The fragile characteristic of medical logistics and strict transporting requirements, especially on a global scale, is very problematic.

The Logistics Challenge For Vaccines

The logistics network capacity, especially cold-chain network capacity, is simply not enough to support distribution at this scale. Vaccines are temperature-sensitive high-value commodities. They are required to be transported in a climate-controlled environment, from beginning to end, to protect the quality and the effectiveness of vaccines.

The difficulty of cold-chain transportation is that each tool and equipment used in the logistics system must be specialized to meet the rigid cold-chain regulations and laws. Any breach in the cold chain could result in the whole batch of vaccines being unusable – an expensive mistake that no logistics company can afford to make.

What makes the transport process of the COVID-19 vaccines even more challenging is that some COVID-19 vaccines require a significantly more stringent transport environment than the conventional vaccine. Conventional vaccines are usually stored at temperatures between 2°C and 8°C, while some COVID-19 vaccines require to be transported at temperatures below -80°C.

This further poses obstacles to logistics companies as only a small subset of available logistics infrastructures and equipment can handle these kinds of transport requirements.

Furthermore, vaccines are usually shipped within the belly hold of the passenger aircraft rather than the dedicated cargo aircraft as it can help vaccines get closer to the final destination. The reduction of commercial passenger flights due to low demands and global travel restrictions caused by COVID-19 create more chaos in the distribution chain, forcing specialized freight trucks to play a greater role in moving vaccines to rural or remote locations.

Vaccine Storage And Transportation Guidelines

All levels of government and health authorities have set out clear guidelines and rules on how to safely store, transport, and handle vaccines. Vaccines transporters and couriers have the responsibility to protect vaccines from heat, excessive moistures, light exposures. Couriers should designate trained individuals to manage and monitor the entire process of vaccine transportation.

Protecting the cold chain’s integrity is the top priority of any couriers, and couriers should be equipped with the appropriate equipment, vehicles, and tools to prevent any temperature breach.

Truck vehicles with a dedicated insulated storage container equipped with thermometers and fail-safe door closing mechanisms should be used to transport vaccines. Vaccine temperature must be maintained within a certain range dictated by vaccine manufacturers’ instructions throughout the trip. The door of the truck container should be kept closed as much as possible.

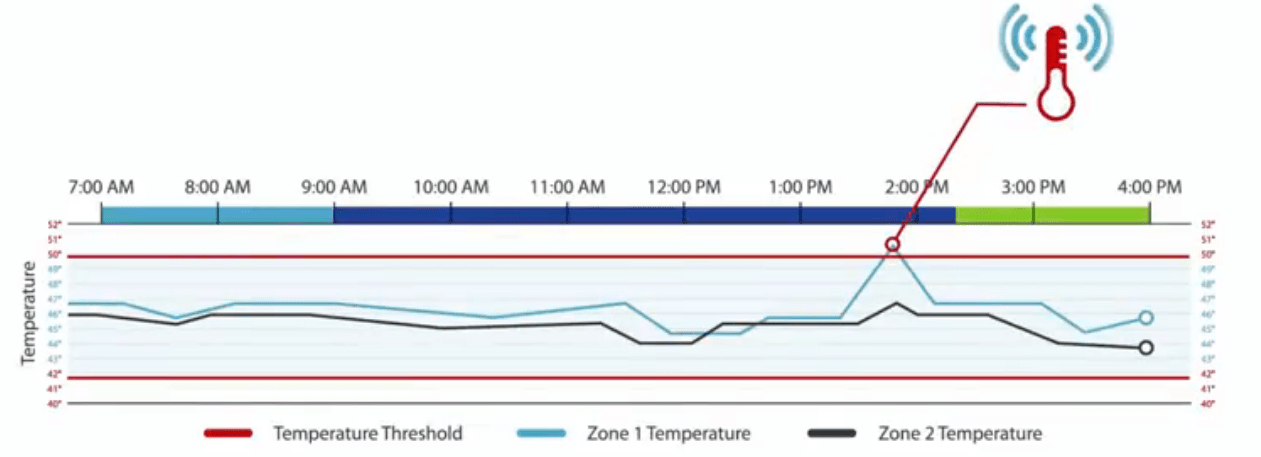

It is important for couriers to monitor and keep track of temperature periodically to ensure that the cold chain is maintained. A temperature log that documents the vaccine temperature along the trip should be kept for future inspection or review. Couriers must report any cold chain accidents or breaches that occurred during the trip to the local public health department seeking further instructions on vaccines’ use or disposal.

Transporting Vaccines: Leveraging Telematics With Limitless Functionality

Temperature Monitoring Sensors

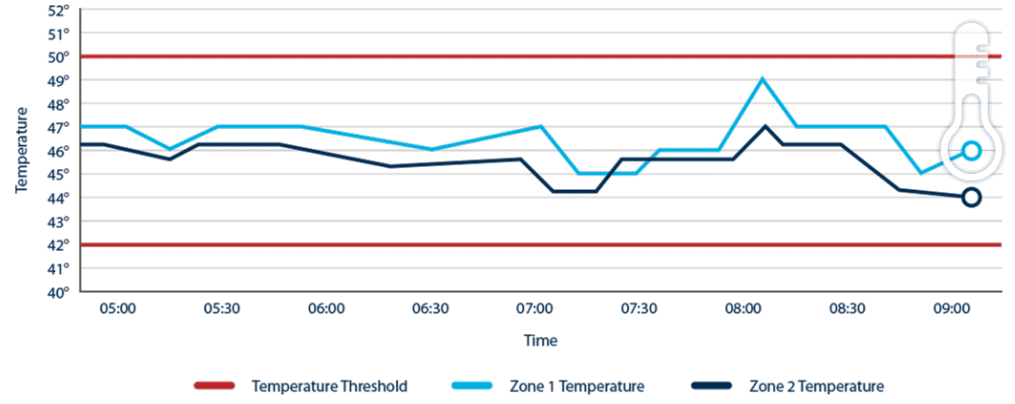

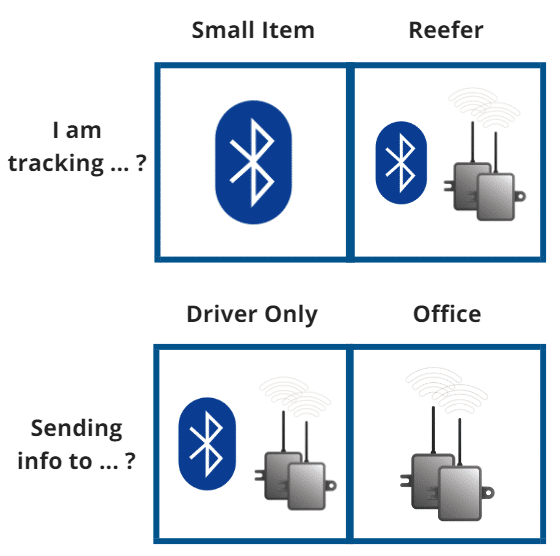

The complexity of the vaccine cold chain makes it difficult for humans to monitor and keep track of the whole process, and this is where telematics technologies supports the movement of temperature-sensitive cargo. Precision temperature sensors are the key tool in collecting and providing accurate ambient temperature reading of the container to the drivers and fleet managers.

This is different from the traditional temperature monitoring sensors that only measure the blower output air temperature. Ambient temperature reading provides a much more accurate representation of the actual temperature in the trailer as it takes into consideration the conveyor effect of cold and warm air variations caused by opening and closing doors. Smart temperature sensors also have one huge advantage over traditional technology – thanks to its high digital connectivity. Drivers and fleet managers can receive real-time updates and alerts of container temperature, so early intervention could be taken when a problem happens.

Moisture and Humidity Monitoring Sensors

Temperature is not the only metric that matters when transporting vaccines; moisture and humidity are the other two essential metrics to consider and monitor when moving vaccines. This is especially critical when transporting vaccines in high humidity regions, where there is a risk of moisture damage caused by condensation. Modern-day telematic sensors have functionality to measure, analyze, and report these readings in real-time to drivers and fleet managers, offering them a comprehensive look at trailer status.

Motion Detection And Optical Sensors

Frequent opening of the trailer door is one the top factor resulting in a cold chain breach. The trailer’s temperature can drastically change within a short period as warm air flows into the container when leaving the door open. For example, studies have shown that temperature can fluctuate up to 10°C when doors are left open for 5 minutes.

The governmental guidelines recommend that couriers should keep the door locked as much as possible to reduce the introduction of warm air and direct sunlight to the trailer. This is why optical sensors and motion detection sensors are necessary tools in helping drivers and couriers to monitor door status. They can immediately notify drivers and fleet managers in case of a door problem, lock failure, or improper door handling. Because of these sensors’ high sensitivity, any slight changes in the ambient environment could be captured and automatically reported to drivers and fleet managers so proper actions could be taken, avoiding expensive mistakes.

Smart Analytics And Troubleshooting System

When a temperature breach happens, couriers and fleet managers need to react and identify root causes to prevent further damage and financial loss quickly. However, finding the root causes might not always be an easy process, as there could be many factors contributing to a cold chain accident.

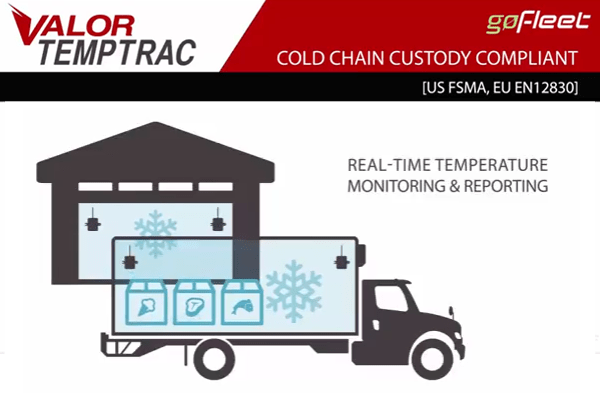

Having a smart telematics solution package can simplify the troubleshooting process and save valuable time and money for couriers. Many telematics tools that focus on temperature monitoring can provide real-time analytics of historical data and generate cold-chain custody reports. Fleet managers can even access and retrieve historical data from anywhere and identify issues.

Generating and keeping a copy of the cold chain custody report is also a mandatory step in fulfilling regulatory requirements. Preparing a historical record of the trailer’s temperature is required for any potential inspections, and the telematics solution completes all the data organization and analysis for you automatically.

Cloud-based Data Storage Solution

The advanced cloud-based data storage solution included in telematics solutions ease the process of storing complicated data history and all the paperwork. The combination of smart hardware and convenient software shape an uninterrupted connect workflow giving drivers and fleet managers maximal visibility and control of key assets.

Best of all, all the temperature monitoring sensors, humidity and moisture sensors, optical and motion sensors are integrated into one simple plug-and-play tracking device that is low-cost and easy to install. Installation can usually be completed within minutes, eliminating any impacts on your fleet operations.

The transportation and distribution of COVID-19 vaccines require a collaborative global effort between all levels of transport chains. A small mistake in the cold chain transport can undermine the quality and effectiveness of the entire batch of vaccines, costing businesses and couriers substantial money.

Investing in smart temperature monitoring and asset tracking solutions can help businesses and couriers avoid making expensive mistakes and accidents and accelerate the safe distribution of COVID-19 vaccines across the world.

Did our piece about transporting vaccines interest you in learning more about how telematics technology can help your fleet? Speak with one of our cold chain tracking specialists to see how to upgrade your fleet and technologies to prepare for the upcoming challenge.