Your residents judge city services by one thing: whether their trash gets picked up on time.

Behind every clean street and satisfied household is a fleet of vehicles running a tight, silent operation—or not. For too many municipalities, outdated tools, paper logs, and guesswork are still running the show.

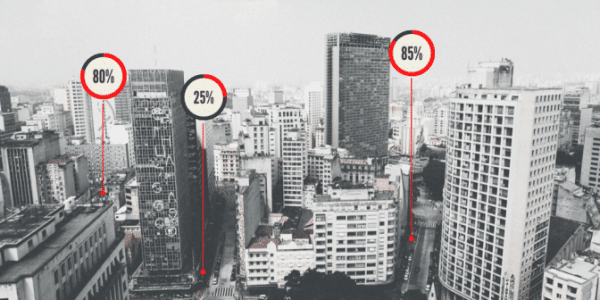

But the most progressive cities are making the switch to telematics—and seeing results. From live tracking to predictive maintenance and driver accountability, smart fleet management is transforming public waste operations.

In fact, predictive maintenance alone can reduce vehicle downtime by up to 50%.

In this article, we’ll break down how data-driven tools are helping municipalities modernize faster, reduce costs, and deliver cleaner, safer streets—without adding more trucks.

1. The Old Playbook Is Costing Cities More Than They Know

Municipal waste fleets weren’t designed to be inefficient—but that’s exactly what they’ve become when left to outdated systems.

Missed pickups. Reactive maintenance. Confusing route overlaps. Paper-based logs and driver reports that don’t reflect real-time performance. These aren’t just small inefficiencies—they’re public-facing failures that frustrate residents, strain crews, and spike operational costs.

Without real-time data, municipal fleet managers are stuck making decisions based on outdated assumptions instead of evidence.

Use Case: A mid-sized city using static routing and paper logs had no visibility into why complaints were rising. A telematics rollout revealed inefficient bin collection patterns and idle-heavy vehicle use—fixable issues they couldn’t see before.

Next, we’ll break down one of the most critical upgrades: tracking vehicle maintenance in real time to reduce downtime and protect public service continuity.

2. Vehicle Maintenance Tracking: From Emergency Fixes to Predictive Uptime

When a garbage truck breaks down mid-route, it doesn’t just delay collection—it creates a ripple effect that impacts public satisfaction, reroutes crews, and increases operating costs.

The problem? Most municipal fleets still rely on reactive maintenance, waiting for something to go wrong before taking action. That’s a costly habit.

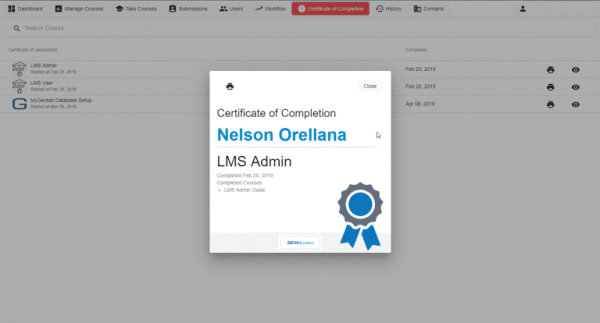

Smart fleets take a predictive approach:

- Real-time engine diagnostics flag faults before breakdowns

- DVIRs (Driver Vehicle Inspection Reports) trigger automated maintenance workflows

- Historical data pinpoints recurring issues and helps forecast part replacements

Use Case: One city reduced downtime by 37% after integrating fault-code alerts and digital inspection reports, streamlining their entire repair cycle.

The result: Fewer breakdowns. Longer vehicle lifespans. And better service delivery, every day.

Next, we’ll shift to how cities can boost service efficiency while cutting back on fuel and labor through smarter route and resource optimization.

3. Public Service Efficiency: Better Routes, Fewer Trucks, Happier Residents

In waste management, efficiency isn’t just about saving fuel—it’s about keeping promises to the public.

Missed streets, overflowing bins, and inconsistent pickup times erode trust fast. And too often, cities try to solve it by adding more trucks or more labor—without fixing the root problem: poor route and resource planning.

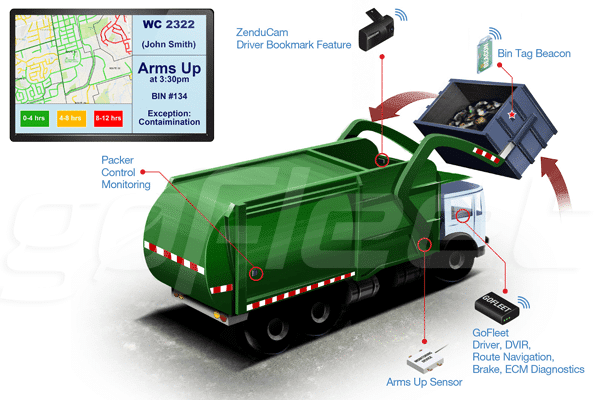

How telematics turns it around:

- Smart routing tools adjust dynamically to traffic, delays, or bin fullness

- Real-time trip histories verify completed routes and service gaps

- Bin-level sensors help avoid unnecessary pickups and prevent overflows

- Live vehicle tracking reduces overlaps, delays, and idle time

Use Case: A municipality trimmed weekly fuel costs by 15% just by avoiding half-empty bin pickups and rerouting on the fly.

Better routes = fewer trucks = cleaner streets.

Next, we’ll cover how to ensure those trucks—and the people driving them—are always operating safely and in full compliance.

4. Safety & Compliance: Make Accountability the Standard, Not the Exception

Every municipal fleet operates in public view—and one safety incident can spark headlines, lawsuits, or revoked contracts.

Yet many cities still rely on after-the-fact reports, hearsay, or incomplete logs to track driver behavior.

Modern fleets don’t wait for complaints—they prevent them with real-time visibility and built-in accountability.

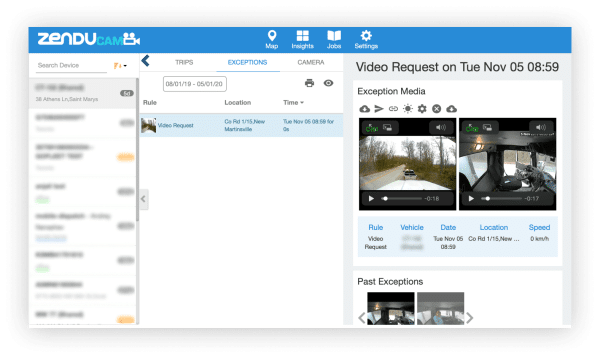

What telematics makes possible:

- AI dash cams that detect speeding, tailgating, and distracted driving

- In-cab alerts that correct unsafe behavior instantly

- Automated DVIRs and ELD tracking to meet DOT and FMCSA standards

- Full incident playback to investigate claims and exonerate drivers

Use Case: After installing safety monitoring tools, one city cut reportable incidents by 40% and reduced insurance premiums in the following year.

Safety isn’t just a compliance box—it’s a cost saver, a risk mitigator, and a public trust builder.

Next, we’ll break down how municipalities can go beyond day-to-day operations and make data-driven resource decisions that boost productivity.

5. Resource Allocation: Use the Right Vehicle for the Right Job—Every Time

Overusing some trucks while others sit idle isn’t just inefficient—it’s expensive. And in municipal operations, misallocated resources lead to missed pickups, wasted fuel, and underperforming assets.

Most public works departments don’t lack equipment—they lack visibility into how that equipment is being used.

Here’s how telematics solves that:

- Live dashboards show asset utilization across the entire fleet

- Geozones track which vehicles service which districts—and how often

- Trip history reveals overlap, underuse, and gaps in service

- Idle time reports flag misuse and wasted fuel

Use Case: A city identified underused rear loaders assigned to high-density routes. Swapping them for higher-capacity units saved 11 man-hours per week and reduced overtime spend.

By aligning vehicle type, location, and workload, municipalities can stretch resources further—and deliver more consistent service.

Up next, we’ll talk about the elephant in the room: public budgets—and how smarter fleet data cuts costs without cutting corners.

6. Operational Cost Management: Stop the Bleed Without Sacrificing Service

Public services don’t get a blank check—especially waste operations, where every dollar is scrutinized by residents and city councils alike.

But hidden costs add up fast: fuel from inefficient routes, unplanned maintenance, duplicated coverage, and overtime from poor planning.

Telematics helps municipalities cut waste—literally and financially.

Here’s what smarter fleets track to control costs:

- Fuel consumption trends and idle time reports

- Maintenance spend per vehicle vs. lifecycle stage

- Cost-per-route and per-pickup metrics

- Verification of completed service to avoid refunds or rework

Use Case: After implementing route tracking and driver behavior monitoring, one town reduced fuel costs by 18% and recovered $25,000 annually in false damage claims.

With real data, municipalities don’t need to sacrifice service to meet their budget—they just need better tools.

Let’s wrap with how cities can use this visibility not just to manage today’s fleet—but to plan tomorrow’s.

7. Fleet Modernization: Replace Guesswork with Lifecycle Strategy

Replacing a garbage truck isn’t a quick decision—it’s a major investment. But too often, cities rely on age or mileage alone to make those calls.

That’s not fleet strategy. That’s guesswork.

Telematics gives municipalities a full picture of true asset performance—so they can make smarter replacement, rental, or retrofit decisions.

Here’s how it works:

- Total cost of ownership (TCO) tracking by vehicle

- Historical maintenance cost vs. value comparison

- Downtime analysis to flag underperformers

- EV readiness and utilization scoring for future fleet planning

Use Case: A regional district delayed two truck replacements after TCO data revealed they were still outperforming newer models—saving over $300,000 in capital spend.

Modernizing your fleet isn’t just about buying new—it’s about knowing which vehicles deliver the most value.

Let’s bring it all together with a final message on the role of data in running a cleaner, smarter, more efficient city.

8. Final Thoughts: Cleaner Cities Start with Data-Driven Fleets

The success of municipal waste operations doesn’t depend on having more trucks—it depends on knowing what every truck is doing, every hour, every route.

From missed pickups to maintenance chaos and rising costs, most problems in public fleet operations come down to one issue: lack of visibility.

Telematics solves that—giving municipal teams the tools to see further, respond faster, and deliver more with less.

And when cities operate smarter, streets stay cleaner, residents stay happier, and public trust stays strong.

Transform Your Municipal Fleet with Real-Time Visibility

GoFleet helps municipalities modernize waste operations with end-to-end telematics—from route tracking to predictive maintenance and safety automation.

With our platform, cities gain full control of their fleets and real data to drive every decision.

Book a demo today and start building the smarter fleet your city deserves.