Employing asset tracking solutions for your construction business allows you to access and assess critical performance data of your assets in real-time, whether you’re on-site or not. When you can collect and access data, you’re able to maximize the utilization of assets that are essential for the daily operations across your sites and operations

With so many asset tracking and management options available to the construction industry, it’s difficult to know which one is the best option for you. In this post, we’ll help guide you towards the best choice for your assets and your business. Below, we’ve listed some of the most important things that asset trackers can provide to your construction business.

Modular Construction Tracking

Building something offsite? Modular projects require many of the same protocols as on-site builds. “There’s definitely a benefit, especially depending on how they’re putting these modules together,” says William Hudson one of GoFleet’s Sales Consultant’s. “I’ve had a use case with a construction company that wanted different asset tracking for different pieces of pipe. So they had a lay down yard, then put an asset tracker on everything to differentiate which piece was which, as well as where they were located at any given point in time.”

Asset trackers have a number of similar applications, allowing project managers to access critical data, such as equipment details and materials used. “So now, instead of walking through a massive field of all these different parts, you can actually know exactly where they’re located by the name of the device, instead of wasting time and productivity looking for each individual piece,” says Hudson.

Reduced Theft

One of the biggest challenges facing the construction industry is theft. People will often target small assets because they can be hidden and removed easily. But even larger assets are at risk for theft. Asset trackers come in a variety of shapes and sizes, helping improve the security of your construction assets and reduce the risk of theft and loss by tracking and tagging your tools, machinery, vehicles, equipment and building materials.

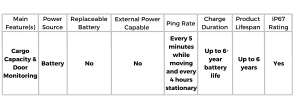

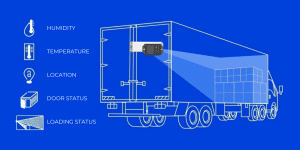

As an example, GoFleet’s BeWired asset tracker is an end-to-end asset tracking solution for non-vehicle assets of all sizes, including trailers, dry containers and heavy equipment. BeWired can be integrated by third-party software to provide data such as movement alerts, detailed location and movement history, triggering updates and much more.

More Safety For Your Construction Workers

Recent reports claim that accidents on a construction site are among the most frequent causes of injury or accidental death. Faulty equipment represents significant safety hazards to workers on your site; by effectively tracking, managing and maintaining construction machinery and other assets, you can help prevent accidents.

Schedule Repairs And Maintenance

Your site’s assets are critical for your business operation. One of the most important factors in managing construction equipment and tools involves knowing exactly what you have and how much they cost to operate. It’s also important to know when your assets require maintenance, repair or replacement.

Use asset tracking to record an asset’s lifecycle and determine its peak performance, as well as when it needs to be repaired. “When an asset is actually plugged into a vehicle, you’re getting a lot more data coming in, like engine health, how the vehicle is being treated, how is this vehicle being driven?” says Hudson.

Construction vehicles are no exception. “If you think in terms of construction, for example an excavator, a spreader, backhoe, trackers can plug into those as well,” Hudson continues. “There’s a lot more data coming in once you plug a tracker into a vehicle, because that vehicle has its own computer.”

Collected data can generate an asset profile that enables you to plan a preventative maintenance schedule and avoid unplanned downtime. By assessing your asset’s overall “health”, you can determine which ones are profitable, and which ones have a greater cost of ownership than your budget allows.

What To Consider Before You Purchase An Asset Tracker For Your Construction Business

Asset trackers can be used in the construction industry in a number of different ways, and most solutions are scalable, meaning they can apply to small and medium construction businesses, as well as larger construction enterprises with multiple sites and plants.

As part of a comprehensive, end-to-end solution service, GoFleet can help you choose the right asset tracker for your construction operation. Here are some of the key pieces we would help you determine before making a purchase decision:

What Data Can Your Asset Trackers Provide?

In construction, the asset lifecycle starts with the decision to acquire or rent an asset, which can then be identified and tracked from acquisition to removal.

The right asset tracker can gauge the entire cycle process of your assets, allowing contractors and project managers to determine the operational lifespan of an asset. By tracking your equipment, tools, plants, and vehicles, construction companies can begin to understand the need for certain assets and help avoid costly outcomes such as unplanned downtime. It also enables you to figure out the remaining service life of all assets, so you can plan ahead and invest in new equipment when needed. From these data sets, you could ostensibly create reports such as maintenance schedules to help your assets operate at maximum efficiency.

Is Data Tracked In Real-Time?

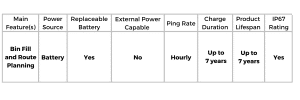

Real-time tracking produces specific data around asset usage and location. An effective asset tracker can help you register and account for all of your construction assets; knowing their exact location helps increase productivity and reduce job lead times. For example, GoFleet’s BeWired asset tracker comes network and application-ready, protecting and tracking your equipment and other assets with a detailed history of their movement and location, usage reports, maintenance monitoring to prevent breakdowns, misuse alerts and more.

Do Your Employees Need Training?

Depending on the teams that require access, you’ll need to know how much training your workers need to operate the trackers. You should also be aware of training costs and how long it takes to train key stakeholders. The BeWired trackers are easy to install, maintenance-free and there’s no reader required, providing full support for a large number of devices and workers.

Conclusion

Asset tracking allows your business to maximize the assets you have, as well as their utilization. By using them within the construction industry, asset tracking also allows project managers, contractors and managers to enhance the lifespan of their assets, and improve business operations. At GoFleet, our consultants will help you identify your company’s goals, as well as determine the trackers you need based on size and scope, to deliver optimal results. Moreover, our experts will help you build an asset tracking system that’s scalable and can evolve with you as your business continues to grow. Contact us today!