Fleet management has become a pivotal element in the operational toolkit of modern enterprises. The administration and coordination of a company’s vehicle fleet can range from a handful of cars to a national armada of trucks, ships, or planes. The overarching objective of fleet management is to oversee all fleet performance and fleet maintenance in order to increase productivity and ensure the smooth operation of an enterprise’s transportation segment.

According to AutomotiveFleet.com, fleet costs continue to rise as a result of inflation for fuel and operation costs, as well as supply chain issues. Nearly every aspect of fleet management hinges on money, highlighting how crucial meticulous fleet management is, not only as a means of controlling costs but also in enhancing the reliability and availability of the fleet itself.

Fleet management has evolved from mere vehicle maintenance to encompass a wide array of functions—such as driver management, fuel economy, regulatory compliance, and integration with other back-office systems. These advancements come against the backdrop of increased environmental awareness, technological integration, and an ever-present drive for cost efficiency.

In this article, we will dive into the essential components that constitute effective fleet management, the transformative role technology plays in this sector, and the ways in which fleet efficiency and productivity can be improved. We’ll also explore the imperatives of maintenance and safety protocols, navigate through the complexities of cost management, and understand the criticality of compliance with regulations.

Finally, we will guide you through the process of choosing the right fleet management solutions tailored for your enterprise and peer into the future trends that are poised to redefine the landscape of fleet management.

What is Fleet Management?

This comprehensive term encompasses a range of activities, from the maintenance of vehicles to the management of drivers, the tracking and monitoring of vehicles in real-time, and the optimization of the fleet for various purposes such as efficiency, safety, and regulatory compliance. Fleet management’s scope is not just confined to the tracking of physical assets; it extends into the strategic realm, contributing to decision-making processes that affect the entire business.

The Evolution of Fleet Management in Enterprises

Historically, fleet management was primarily reactive—focused on repairing vehicles when they broke down and managing drivers’ schedules. Today, it has transformed into a proactive, strategic process backed by sophisticated technologies and data analytics. This evolution has been propelled by the emergence of software and hardware that provide real-time data, enabling enterprises to anticipate issues, streamline operations, and harness efficiencies at scale.

For instance, advances in telematics have revolutionized how enterprises track and manage their fleets, providing granular data on vehicle location, driver behavior, vehicle usage patterns, and more. What was once a ledger-based log of vehicle usage has now become a complex data-driven ecosystem that is integral to enterprise operations.

Key Components of Fleet Management

- Vehicle Tracking: Vehicle tracking systems form the backbone of modern fleet management. By using GPS and other navigation systems, businesses can gain immediate insights into their vehicles’ locations. This information is not only vital for operational efficiency—ensuring that vehicles are where they need to be when they need to be—but also for security and theft prevention.

- Driver Management: The human element of fleet management is just as important as the mechanical. Managing drivers involves scheduling, driver safety programs, performance monitoring, and ensuring that they comply with both internal policies and external regulations. Effective driver management can lead to reduced risk, lower operational costs, and improved fleet efficiency.

- Fuel Management: With fuel costs constituting a significant portion of a fleet’s operational expenses, managing fuel consumption is a top priority. This includes monitoring fuel usage, optimizing routes to reduce unnecessary fuel expenditure, and implementing policies to ensure that drivers are operating vehicles as efficiently as possible.

- Maintenance Scheduling: Proactive maintenance scheduling helps enterprises avoid the downtime and costs associated with unexpected vehicle breakdowns. This involves regular inspections, servicing, and repairs, which are all scheduled to minimize disruptions and extend the life of the vehicle.

- Compliance and Reporting: Regulatory compliance is a critical aspect of fleet management. Enterprises must ensure that their fleets adhere to a multitude of regulations, from emissions standards to driver working hours. Additionally, reporting is essential for both internal performance reviews and external regulatory compliance, including the recording and analysis of data related to accidents, breakdowns, and maintenance.

Incorporating these components into a cohesive fleet management strategy is critical for enterprises seeking to maintain a competitive edge. Effective fleet management not only streamlines operations but also ensures that fleets are well-maintained, compliant, and operated in a cost-efficient manner.

The Role of Technology in Fleet Management

The integration of technology in fleet management has been nothing short of a revolution, introducing levels of efficiency and control that were previously unattainable. Central to this technological advancement are fleet management software and telematics, which have transformed the way enterprises track and manage their fleet operations.

Introduction to Fleet Management Software and Telematics

Fleet management software is a digital platform that allows for the comprehensive management of all fleet operations from a centralized location. This software can integrate with various sensors and trackers installed in vehicles, enabling fleet managers to monitor everything from vehicle health to driver behavior in real-time.

Telematics, a blend of telecommunications and informatics, has become a buzzword in the fleet management sphere. Telematics systems utilize GPS technology, onboard diagnostics (OBD), and mobile apps to provide a detailed picture of a vehicle’s status and the behavior of its driver. By feeding this information back to the central software system, telematics devices help optimize the entire fleet’s performance.

Benefits of Using Technology for Vehicle Tracking and Diagnostics

By utilizing GPS tracking, enterprises gain real-time visibility into the location of their vehicles, which is critical for route planning, dispatching, and even recovering stolen vehicles. It also allows for geo-fencing, where vehicles are confined to operating within a predefined geographic area, enhancing security and operational control.

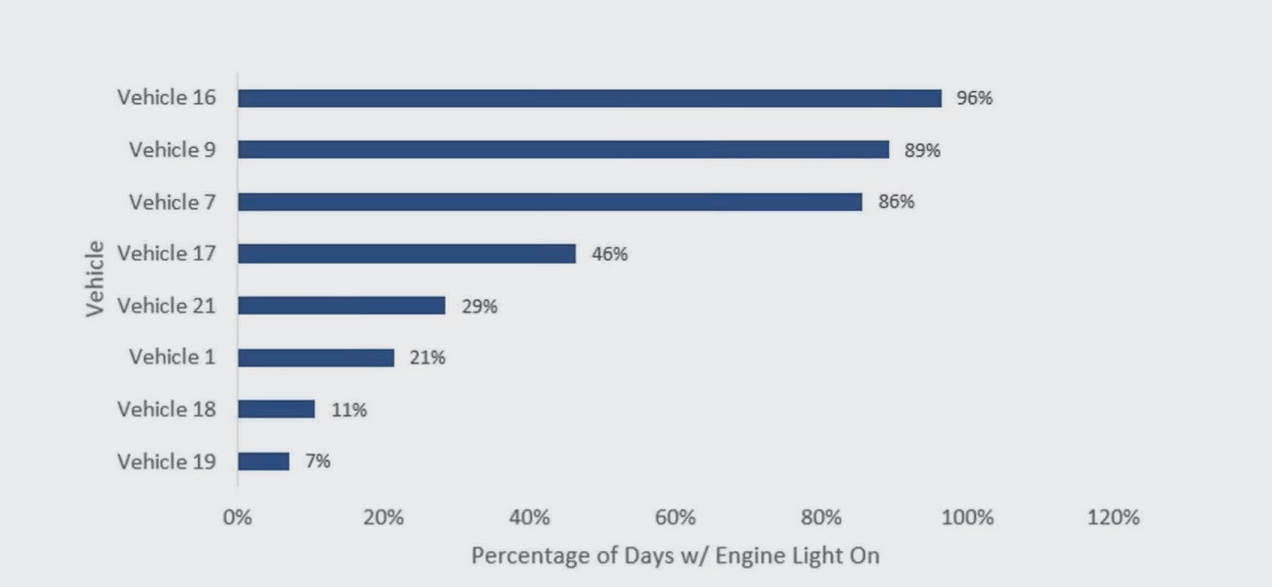

Modern vehicles come equipped with a plethora of sensors and onboard diagnostic capabilities. Fleet management software can tap into this data to provide early warnings about potential vehicle issues, schedule timely maintenance, and even predict when a vehicle might fail. This preemptive approach to maintenance can save enterprises a significant amount of money and prevent costly downtime.

How Technology Enhances Decision-Making in Fleet Operations

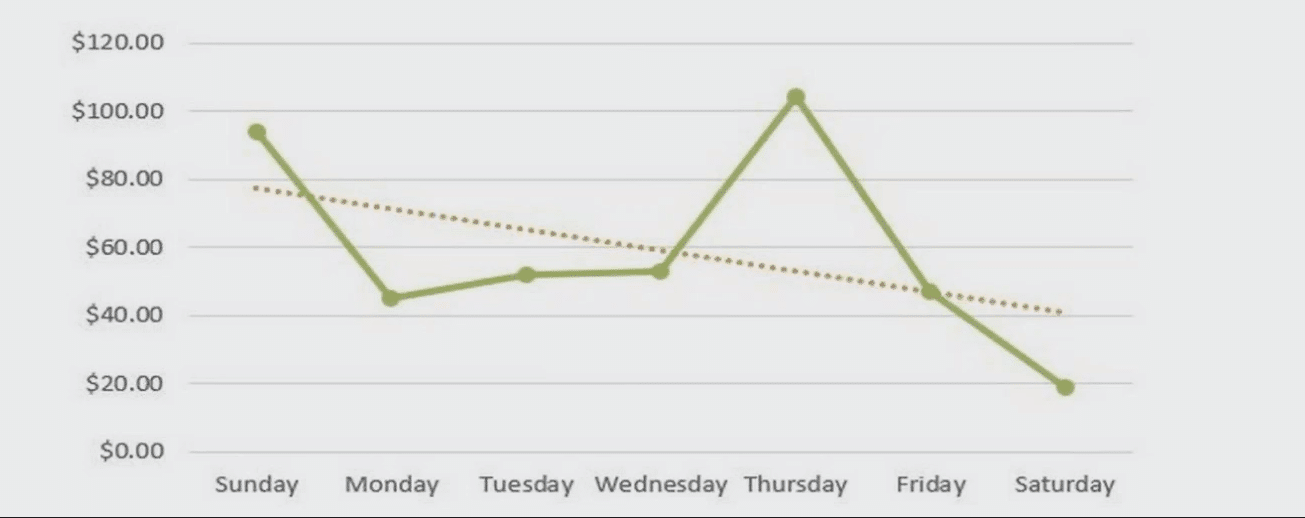

The wealth of data provided by fleet management software and telematics systems is invaluable in strategic decision-making. Fleet managers can analyze trends, such as fuel usage patterns, common vehicle faults, and driver behavior analytics, to make informed decisions that can lead to cost savings and efficiency improvements.

For example, data analytics can identify which routes are consistently slower or lead to higher fuel consumption, allowing for route optimization. Similarly, driver performance metrics can help in developing targeted training programs to improve safety and efficiency on the road.

Moreover, the integration of fleet management software with other enterprise systems, such as HR and finance, allows for a holistic approach to fleet management. This integration ensures that the data is not siloed but is instead contributing to the broader business intelligence, driving overall enterprise performance.

Improving Fleet Efficiency and Productivity

Enterprises of all sizes must focus on optimizing their fleet operations to enhance efficiency and productivity. Achieving this requires the implementation of strategic planning, cutting-edge technology, and continuous performance evaluation. Here, we explore various strategies and techniques that can substantially increase fleet efficiency.

Strategies for Optimizing Fleet Routes and Schedules

Route Optimization: The optimal path between two points is not always a straight line, especially when it comes to fleet routing. Route optimization involves analyzing various factors such as traffic patterns, delivery windows, and vehicle capabilities to determine the most efficient route. Modern routing software can process vast amounts of data to provide routes that minimize travel time and distance, leading to significant savings in fuel and time.

Dynamic Scheduling: Beyond static route planning, dynamic scheduling allows for real-time adjustments to fleet schedules. This flexibility can be crucial when dealing with unexpected events such as traffic jams or urgent delivery requests. Dynamic scheduling can reassign tasks among drivers and vehicles to ensure that the fleet remains productive and delivery times are kept to a minimum.

Techniques for Improving Fuel Efficiency

Driver Behavior Modification: Fuel consumption is significantly influenced by driving behavior. Speeding, idling, and aggressive acceleration can all lead to unnecessary fuel wastage. Training programs focused on eco-driving techniques can encourage more fuel-efficient driving habits.

Vehicle Maintenance: A well-maintained vehicle is a fuel-efficient one. Regular maintenance ensures that engines run smoothly, tires are properly inflated, and aerodynamics are not compromised by unnecessary drag, all of which contribute to improved fuel efficiency.

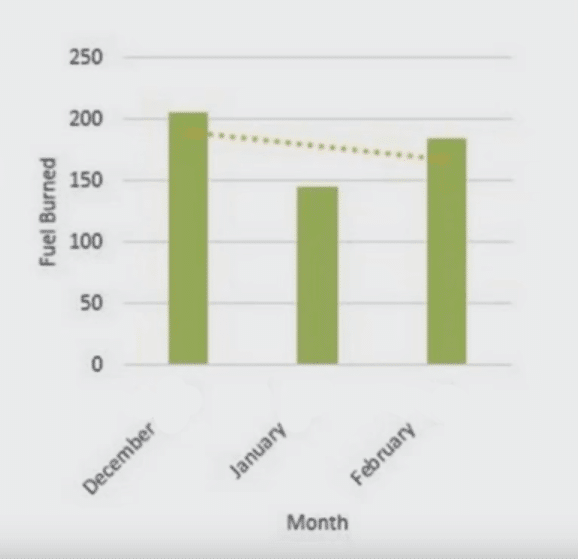

Fuel Management Systems: Implementing a fuel management system can provide insights into fuel consumption patterns and identify areas for improvement. These systems can monitor fuel levels, track fuel purchases, and prevent unauthorized fuel use, ensuring that every drop of fuel is accounted for and used effectively.

Utilizing Data for Performance Benchmarking

Data-Driven Insights: The adage “You can’t manage what you don’t measure” holds true in fleet management. Collecting data from vehicles and drivers allows enterprises to benchmark their performance. This data can be analyzed to set realistic performance goals and to identify underperforming vehicles or drivers.

Continuous Improvement: Benchmarking is not a one-time task but a continuous process. Ongoing analysis of fleet data helps to spot trends, measure the impact of changes, and make informed decisions about fleet expansion, reduction, or reallocation.

Custom KPIs: Every enterprise is unique, and so are its key performance indicators (KPIs). Custom KPIs tailored to specific business goals can be monitored and acted upon, such as ‘cost per delivery’ or ‘deliveries per hour’.

Maintenance and Safety Protocols

An enterprise’s commitment to maintaining its fleet and ensuring stringent safety standards can have a profound impact on operational costs and overall business reputation. Fleet maintenance and safety are inextricably linked—not only do they prevent the premature breakdown of vehicles, but they also safeguard the well-being of drivers and the public.

Importance of Regular Fleet Maintenance and Its Impact on Costs

Regular fleet maintenance is the cornerstone of any robust fleet management program. It extends the life of the vehicle, enhances fuel efficiency, and ensures that vehicles are operating at peak performance. Importantly, routine maintenance can prevent costly repairs down the line by identifying and addressing issues before they escalate.

A study by the National Highway Traffic Safety Administration (NHTSA) has shown that an average of 45,000 accidents per year are caused by a vehicle malfunction, many of those because of poor maintenance. These accidents not only incur direct costs due to vehicle damage and associated liabilities but also indirect costs such as increased insurance premiums and potential damage to the company’s reputation. Consistent fleet maintenance practices can mitigate these risks and contribute to a safer operational environment.

Safety Standards and How They Are Upheld Through Fleet Management

Safety standards in fleet management are not merely recommendations; they are often mandated by law and are critical for the responsible operation of any fleet. These standards encompass everything from vehicle inspections and driver training to compliance with road safety regulations.

Fleet management software plays a crucial role in upholding these standards by providing reminders for vehicle inspections and maintenance, tracking the completion of safety training for drivers, and documenting adherence to safety protocols. This level of oversight helps ensure that no aspect of the fleet’s safety is overlooked.

Implementing Preventive Maintenance Schedules

Preventive Maintenance: Preventive maintenance schedules are designed to keep vehicles in optimal condition by performing maintenance activities at regular, predetermined intervals. These activities may include oil changes, tire rotations, brake inspections, and other vehicle-specific checks.

Maintenance Tracking: Implementing these schedules can be complex, particularly for large fleets. Fleet maintenance software can track maintenance histories and upcoming service requirements, ensuring that vehicles are serviced on time and that records are maintained for warranty and regulatory purposes.

Cost Management: By adhering to a preventive maintenance schedule, enterprises can manage maintenance costs more predictably. It avoids the spikes in repair costs associated with reactive maintenance, where parts are only fixed or replaced after they fail. Moreover, well-maintained vehicles often command higher resale values, further optimizing the fleet’s lifecycle costs.

Cost Management in Fleet Operations

Effective cost management is a pivotal aspect of fleet management, as it directly influences the bottom line of enterprises. A comprehensive understanding of the financial elements involved in fleet operations enables businesses to make informed decisions that lead to significant cost reductions while maintaining quality and reliability.

Understanding the Financial Aspect of Fleet Management

Total Cost of Ownership (TCO): A key concept in fleet financial management is the Total Cost of Ownership (TCO). TCO goes beyond the initial purchase price of a vehicle to include depreciation, financing, insurance, fuel, maintenance, and disposal costs. A clear understanding of TCO helps in making better procurement decisions and in managing the fleet more efficiently over its lifecycle.

Budgeting and Forecasting: Accurate budgeting and forecasting based on historical data and predictive analytics are essential for cost management. By forecasting future expenses, enterprises can allocate resources appropriately, plan for capital expenditures, and avoid unexpected cash flow issues.

Reducing Operational and Ownership Costs

Operational Efficiency: One of the primary ways to reduce costs is by increasing operational efficiency. This includes optimizing routes to reduce mileage and fuel consumption, ensuring vehicles are loaded efficiently to maximize each trip, and implementing idle reduction policies.

Lifecycle Management: Ownership costs can be reduced by managing the lifecycle of each vehicle. This involves regular maintenance to extend the lifespan of vehicles, timely disposal and replacement to avoid the costs associated with aging vehicles, and selecting vehicles with a strong resale value.

Fuel Management: Since fuel is often one of the largest operational costs, implementing a robust fuel management program is essential. Such a program may include monitoring fuel usage, training drivers in fuel-efficient driving practices, and considering alternative fuel vehicles if appropriate.

Balancing Quality and Cost in Fleet Procurement

Value Analysis: When procuring new vehicles, it’s critical to conduct a thorough value analysis that weighs the cost against the expected performance, reliability, and utility. Purchasing cheaper vehicles can lead to higher long-term costs if those vehicles require more frequent repairs or do not meet operational needs.

Vendor Negotiations: Building strong relationships with vendors and leveraging these relationships can lead to cost savings. Bulk purchasing, negotiating better financing rates, and seeking discounts for loyalty or early payment can all contribute to lower costs.

Technology Investments: Investing in technology, such as fleet management software, can initially seem like an additional cost but often leads to significant savings over time. These technologies can streamline operations, improve compliance, reduce the likelihood of costly errors, and provide valuable data for cost-saving decisions.

Compliance and Regulations

Adherence to regulatory requirements is not just about obeying the law; it’s a crucial element of operational integrity and sustainability. The complexity of these requirements can be extensive, but effective fleet management practices play a pivotal role in ensuring that enterprises remain compliant while avoiding costly fines and penalties.

Overview of Regulatory Requirements Affecting Fleet Management

Transportation Regulations: Depending on the location, fleets may be subject to a variety of transportation laws, including hours of service regulations, emission standards, and safety requirements. These regulations are often updated and can vary widely by region and the type of cargo being transported.

Environmental Regulations: With a growing focus on environmental protection, fleets are increasingly required to comply with emissions regulations. This may involve regular vehicle emissions testing and adhering to idling restrictions, and in some cases, may influence the types of vehicles that can be purchased.

Occupational Safety: Regulations around occupational safety and health also impact fleet management. These may dictate the provision of safety equipment, the implementation of driver safety training programs, and requirements for the reporting of accidents and injuries.

Ensuring Compliance Through Effective Fleet Management Practices

Training and Education: Ongoing driver training and education are critical for compliance. Drivers must be up to date on current laws and best practices to ensure that they are not inadvertently in violation of regulations.

Fleet Policies: Developing and enforcing clear fleet policies helps to ensure that every member of the fleet operation understands their role in maintaining compliance. These policies should cover aspects such as vehicle use, maintenance, driver conduct, and reporting requirements.

Record Keeping: Meticulous record-keeping is essential for compliance. Digital logging devices, which are now mandatory in many regions, can help fleets keep accurate records of driver hours. Maintenance logs, fuel usage records, and inspection reports must also be kept up-to-date and readily accessible.

Role of Fleet Management in Audit and Reporting

Audits: Fleet management systems can streamline the audit process by consolidating all compliance-related data in one place. This can include driver logs, maintenance records, and incident reports, making it easier to demonstrate compliance to auditors.

Reporting: Compliance often requires regular reporting to regulatory bodies. Fleet management solutions can automate much of this reporting, reducing the administrative burden and the risk of errors or omissions.

Proactive Compliance: Ultimately, the goal is to shift from a reactive approach to compliance to a proactive one. By utilizing fleet management tools and practices, enterprises can ensure they are consistently ahead of compliance issues, identifying potential violations before they occur, and addressing them swiftly.

Choosing the Right Fleet Management Solution

The right software can transform a fleet’s productivity, but with numerous options in the market, the decision-making process can be complex. Here’s what enterprises should consider to make an informed choice that aligns with their operational goals.

Factors to Consider When Selecting Fleet Management Software

User-Friendliness: The interface of the fleet management solution should be intuitive and user-friendly. A steep learning curve can lead to resistance among staff, and time lost to training could offset the efficiency gains that the software is supposed to deliver.

Features and Functionality: The chosen solution should have a robust set of features that cater to the specific needs of the enterprise, such as real-time tracking, maintenance alerts, fuel management, and reporting capabilities. It’s crucial to differentiate between must-have features and nice-to-haves to ensure the solution meets core operational requirements.

Cost-Efficiency: Cost is always a consideration, but it’s important to look at long-term value rather than just the initial investment. The right solution should offer cost savings through improved efficiency, better compliance, and reduced administrative overhead.

Support and Training: After-sales support and training services are vital. Providers should offer comprehensive support and training to ensure the smooth implementation and ongoing use of the software.

Customization and Scalability in Fleet Management Solutions

Tailored Solutions: Fleet management solutions should be customizable to fit the unique processes and workflows of the enterprise. A one-size-fits-all approach rarely delivers the best outcomes.

Growth Accommodation: Scalability is crucial. The solution must be able to grow with the enterprise, accommodating more vehicles and new types of assets without performance degradation or the need for a complete system overhaul.

Integration with Existing Enterprise Systems

Seamless Integration: To truly enhance operational efficiency, fleet management software should integrate seamlessly with the enterprise’s existing systems, such as HR software, financial systems, and supply chain management tools.

Data Utilization: The ability to aggregate and utilize data from across these systems can provide a comprehensive overview of operations, leading to better-informed decisions and a more cohesive strategy.

Security Considerations: Any integration must also prioritize security to protect sensitive business data. The chosen fleet management solution should have robust security measures in place and be compliant with relevant data protection regulations.

Final Thoughts

As we have navigated through the intricacies of fleet management, it’s clear that this aspect of business operations holds strategic value for any enterprise reliant on transportation and logistics. The landscape of fleet management is vast and encompasses a variety of components, from vehicle tracking to compliance, and from cost management to the integration of cutting-edge technologies.

Fleet management is not merely about overseeing a collection of vehicles. It’s about driving an enterprise towards enhanced performance, improved safety, and robust cost savings. With the right fleet management strategies and tools, businesses can achieve significant operational efficiencies, minimize risks, and capitalize on opportunities to propel their growth and success.

For enterprises looking to stay ahead of the curve, it is imperative to continually evaluate and improve fleet management practices. Whether it’s by embracing new technologies, optimizing fleet operations, or preparing for the transition to electric vehicles, the time to act is now.

Take the next step in advancing your fleet management. Contact a GoFleet consultant today to explore how our solutions can be tailored to your enterprise’s unique requirements and ambitions. Together, we can steer your fleet towards a more efficient, sustainable, and profitable future.