Keeping your fleet in good shape all-year-round can help you maximize productivity and avoid unexpected vehicle breakdowns or service delays. Meaning vehicle maintenance is an essential branch of fleet management.

The core idea of a maintenance program is identifying and addressing “small problems” through routine inspections and repairs before they turn into big ones. Preventive maintenance and corrective maintenance are some of the most common maintenance practices adopted by most businesses, but we want to elevate the existing maintenance strategy to a whole new level. Doing this will deliver a superior and streamlined experience to fleet maintenance teams.

Why Do Businesses Need To Step Up On Fleet Maintenance Management?

Failing to run a proper fleet maintenance program could be fatal to vehicle based businesses. Poor maintenance could lead to frequent vehicle breakdowns, safety concerns, service disruptions, and poor customer satisfaction. Unreliable service could discourage your valuable customers and clients from engaging with your business again in the future.

You don’t want to lose a big deal or valuable partners because of trying to save a little on fleet maintenance. That’s why it’s more important than ever to invest in a reliable and intelligent Computerized Maintenance Management System (CMMS) to protect the corporations’ long-term viability and financial sustainability.

Improve Vehicle Uptime

Downtime can be crippling to businesses, with costs quickly adding up the longer a vehicle is off the road. Even a single vehicle that goes out of service can have an immeasurable impact on the entire fleet operations. Fleet managers have to redistribute tasks and mobilize additional human or asset resources to recover productivity losses. Therefore, it’s necessary to create a comprehensive maintenance plan for the fleet to ensure vehicles remain operational and stay on the road as long as possible.

An unexpected vehicle breakdown could also delay shipments and services. Customer delivery may be delayed, and important deadlines may be missed. Time-sensitive, temperature-sensitive, and perishable goods are also at higher risk of quality degradation, leading to customers rejecting the load. It will be a major loss for the business, and it will disappoint customers who didn’t get their shipment in time. If this situation happens often, customers might lose trust and confidence in businesses, and they may switch to other service couriers.

Businesses cannot afford to experience frequent vehicle breakdowns or lengthy vehicle downtime. That’s why businesses need to adopt preventive maintenance strategies to reduce the likelihood of equipment failures. CMMS is a reliable maintenance tool supporting the monitoring and tracking of vehicle health status and reminding technicians to conduct routine part inspections periodically. Only through frequent inspections and proactive monitoring can the technicians identify the faulty units early and address the issues before it happens.

Reduce Operational And Maintenance Costs

Fleet managers might be hesitant about the initial investment cost of the CMMS. They might be unsure or uncertain whether the investment can be justified. But if you look at the fact that many small problems can quickly grow into more serious and costly maintenance issues if the problem isn’t detected and addressed early, you might want to rethink your decisions.

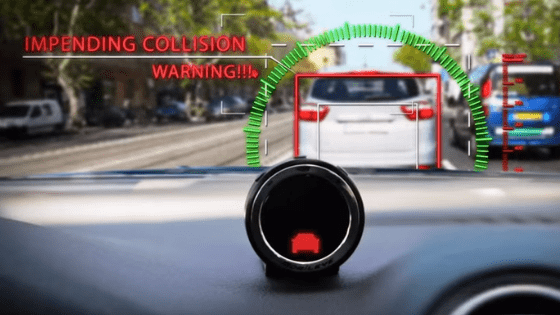

Additionally, just consider how much additional money businesses need to pay if a small vehicle malfunction, such as a flat tire, leads to collisions and roadway accidents. It will not only threaten employees’ and drivers’ health and safety but also result in companies paying huge fines, insurance premiums, or legal issues. As the winter season is fast approaching, it is now more important than ever to ensure vehicles are in the best shape all the time to embrace harsh weather conditions.

Adopting a CMMS can help businesses save money in multiple aspects of the operations, both directly and indirectly. For example, oil changes are among the most important vehicle maintenance routines that every driver or technician must perform. Most vehicles need an oil change every 3,000 to 5,000 miles to keep the engine running efficiently at peak performance and remove particles and sludges accumulated in the filter and tube. However, it will be quite difficult for humans to keep track of the oil change routines and intervals for all the fleet vehicles, especially if the fleet size is relatively large. This is where the CMMS system truly shines as it accurately logs each vehicle’s mileage since the last oil change and reminds maintenance technicians when it’s the time to conduct the oil change. Routine changes and getting the right kinds of oil can improve vehicles’ gas mileage by 1-2%. That doesn’t sound like much of an improvement, but if your businesses own a large fleet, every small saving will accumulate and become quite significant over a long period.

Enhance Drivers’ Safety And Improve Drivers’ And Customers’ Satisfaction

Drivers’ safety is at the centre of everything we do. Vehicle malfunctions such as flat tires and faulty brakes could lead to serious consequences threatening drivers and other road users’ safety. Most businesses are unaware of an accident’s true costs as they only prepare for the direct costs of an accident. Some of the most common hidden costs include loss of labours, downtime of injured workers, maintenance costs for the damaged assets, cost of hiring and training a replacement worker, cost of any fines related to the accidents, and many more. These hidden costs can add up quickly and become a huge financial burden for any business. However, if the business owns a CMMS that can alert fleet managers about the vehicle issues beforehand, all those extra spendings can be avoided.

Poorly maintained vehicles will also affect drivers’ morale and productivity. Drivers will be offended if the vehicle assigned to them is not properly maintained because it will create hindrances in their work. There is nothing more frustrating than a vehicle unexpectedly breaking down during a route and drivers are forced to wait for roadside assistance. This could result in a significant disruption to the service workflow, as it will delay the onboard shipment, and customers might not receive the deliveries in time.

Unique Advantages Of The CMMS

By implementing CMMS, businesses can achieve higher efficiency and control over the assets. The highlight of the CMMS is bringing a high level of automation and digitalization to the entire maintenance process. From wirelessly capturing data from vehicles’ onboard sensors to automatically creating and assigning work orders when issues have been recorded, CMMS is the ultimate tool in designing a well-managed preventive maintenance program.

An intelligent dashboard helps fleet managers utilize assets more efficiently and easily schedule planned maintenance. It can also streamline the entire vehicle parts and components purchasing procedures, as the system can track parts inventory and help you directly order parts to replace faulty units right within the dashboard.

The smart calendar feature displays all the maintenance events and progress in a simple and intuitive user interface, so fleet managers can stay on top of all the maintenance events and not miss any critical alerts. The best feature of the CMMS is that the system can generate over 100 types of highly customizable maintenance reports detailing all the fleet and maintenance data. This is especially useful and valuable to the fleet manager as they can gain real-world insights into fleet performance, identify risk factors, and take appropriate actions to mitigate risks. This could also simplify the company’s internal reporting procedures as the management team could also access these maintenance reports and assess the fleet’s overall status. To provide even more flexibility to businesses, the CMMS is compatible with a wide range of third-party Application Programming Interface (API), allowing users to customize the system to fit their needs.

To conclude, dedicated fleet maintenance software is an essential piece of equipment for any businesses that are looking to improve fleet efficiency and make real cost savings over the long run. If your business wants to get on board and is looking for innovative ideas and solutions that can bring your fleet operations to the next level, work with one of our industry-specific specialists to see how we can create a maintenance software system like ZenduMaintenance personalized just for your business.